©Kingspan

Kingspan’s mission is to accelerate a net zero emissions future built environment with the well-being of people and planet at its heart.

In 2020, Kingspan launched their Planet Passionate programme, with the aim to play an important role in helping tackle three urgent global challenges-

- Climate change

- Circularity

- Protection of the natural world

Through the programme, Kingspan will: contribute to the world’s renewable energy mix, reduce carbon emissions, divert waste from landfill, conserve water, provide upcycling solutions for plastic waste and help clean the world’s oceans and protect biodiversity.

At Kingspan Insulated Panels, their QuadCore insulated panels offer 25-year performance and protection for the buildings you design, build and work in and for the health of the planet. QuadCore technology offers benefits across 4 key areas:

- Thermal Performance

- Fire Performance

- High Environmental Performance

- QuadCore Assured Warranty

They are also on a journey to further reduce the carbon impact of their insulated panels with their new QuadCore Lower Embodied Carbon range, developed specifically to help reduce the carbon footprint of the buildings it is used on.

©BrettMartin

Brett Martin’s dedication to sustainability is evident through:

- 50% of energy consumed is from renewable source

- 100% of Postproduction waste is recycled

- 100% of recyclable waste materials recycled

In March 2018, Brett Martin engaged in a partnership with Lightsource BP, facilitating a direct link to a 6.4MWp solar farm, delivering 14% of the company’s energy requirements.

Brett Martin maintains an exhaustive recycling approach encompassing various inbound packaging materials such as wood, paper, plastic, and metal.

This initiative generates ample clean solar energy, equivalent to powering over 1,600 households and preventing about 3,700 tons of carbon emissions annually – akin to removing nearly 1,800 cars from roads. In 2011, Brett Martin was an early adopter of wind energy, installing a wind turbine that met 11% of energy demands. The affiliation with Lightsource significantly amplifies the Company’s renewable capacity, underlining its steadfastness to eco-conscious manufacturing methods.

Over the past 3 years, the Company has recycled 94% of its post-production waste, with the remainder dispatched to external recyclers. Waste reduction benchmarks are continuously evaluated via management scorecards, effectively communicated across factory tiers and senior leadership, ensuring consistent high-level performance.

©EJOT

To facilitate this goal, the “Greenhouse Gas International” communication tool was introduced in early 2021 after a directive from the company’s leadership. This initiative extends across their global sites as they progressively work towards climate neutrality. Incorporating eco-friendly practices starts from the planning stages for new and renovated structures, like EJOT Turkey, EJOT U.K , and EJOT SE to decrease CO2e emissions.

Aligned with their centenary year in 2022, EJOT has embraced three fundamental principles, marking a path towards achieving carbon neutrality by 2035:

- Embrace sustainable thinking

- Enhance operational efficiency

- Foster a green energy supply

Demonstrating their commitment to localised environmental efforts, EJOT actively engage in regional climate protection.

In 2022, their reforestation initiative, TREEATHLON® transformed brownfields into thriving forests in Germany and Great Britain.

Additionally, EJOT’s involvement in a local energy generation project in France exemplifies their dedication to renewable energy production and distribution.

EJOT’s initiatives to conserve energy and boost efficiency serve as an effective catalyst for driving the transition towards a sustainable and carbon-neutral corporation.

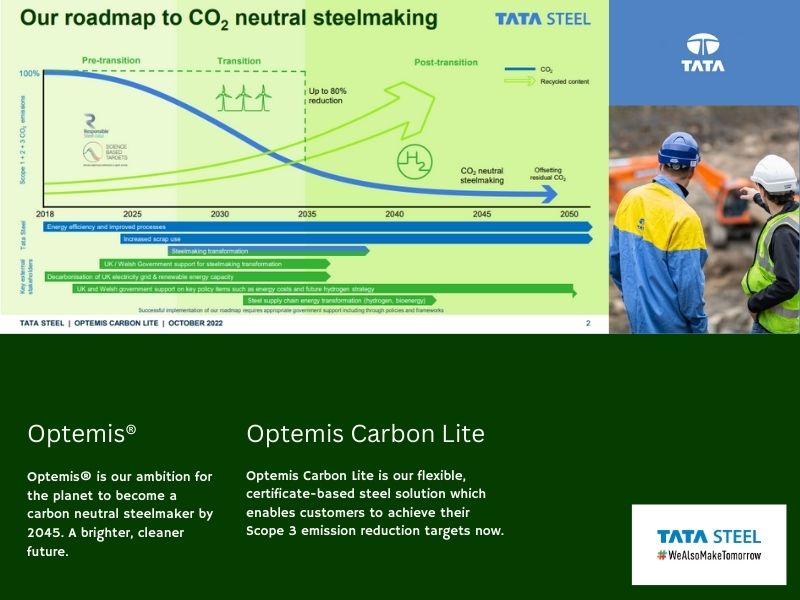

In the pursuit of a net-zero world, steel plays a pivotal role in various domains like renewable energy endeavours, electric mobility, and eco-friendly construction.

Tata Steel UK recognise the existing steel manufacturing process contributes to CO2 emissions. To help reduce this Tata Steel UK is fully committed to:

- curbing emissions within its UK operations achieving carbon-neutral steel production by 2045 including the adoption of Science Based Targets with a reduction in CO2 emissions of up to 80% by 2035 compared with a 2018 baseline.

To realise this objective, they are exploring diverse technological avenues and engaging in comprehensive talks with the UK Government.

The path to carbon-neutrality by 2045 necessitates an overhaul of Tata’s iron and steel manufacturing procedures, which will span multiple years.

During this transition they are actively engaged in an array of initiatives aimed at minimizing CO2 emissions, aligning with their commitment towards carbon-neutral steel production.

Each of these initiatives contributes to Tata Steel UK’s ongoing efforts to diminish their carbon footprint. Such efforts include Tata Steel UK’s low CO2 steel offering Optemis® Carbon Lite available across their product range (https://www.tatasteeleurope.com/construction/Building-systems-uk/sustainable-product-decarbonisation).

Undoubtedly, the endeavour to meet society’s expectations for carbon-neutral steel production poses ambitious challenges, yet, Tata Steel UK boasts a rich legacy of responsibly overcoming such challenges.

They fundamentally believe in fostering the low-carbon production of steel for the future of society.